Quicker fixes, hands-free, when thyssenkrupp Elevator’s service technicians use Microsoft HoloLens

Stairs are great for a workout and a necessity during emergencies. But when you need to get up several floors fast, nothing beats an elevator.

As more people flock to cities with ever-higher skyscrapers, elevators are more important than ever, providing a rapid means of transportation, whether it’s a new resident getting to his apartment or a business woman taking one up to an important meeting. More than 12 million elevators transport upwards of 1 billion people every day and the global elevator industry’s value is more than $44 billion a year.

With 1.2 million units, customers in 150 countries and more than 50,000 employees, thyssenkrupp Elevator knows a thing or two about keeping elevators running. One of the top four manufacturers in the world, they’re teaming up again with Microsoft to help people get to where they need to go with as few delays as possible.

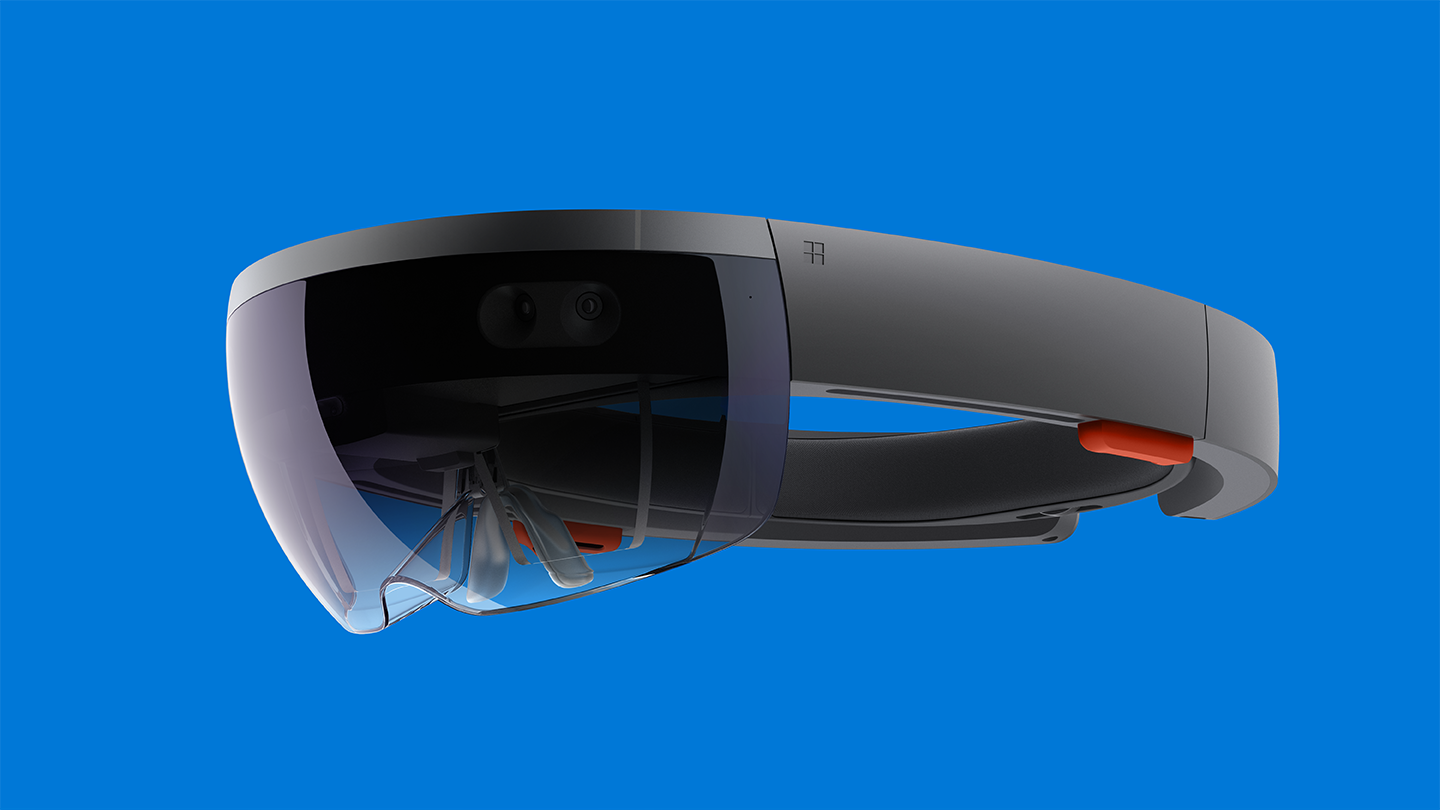

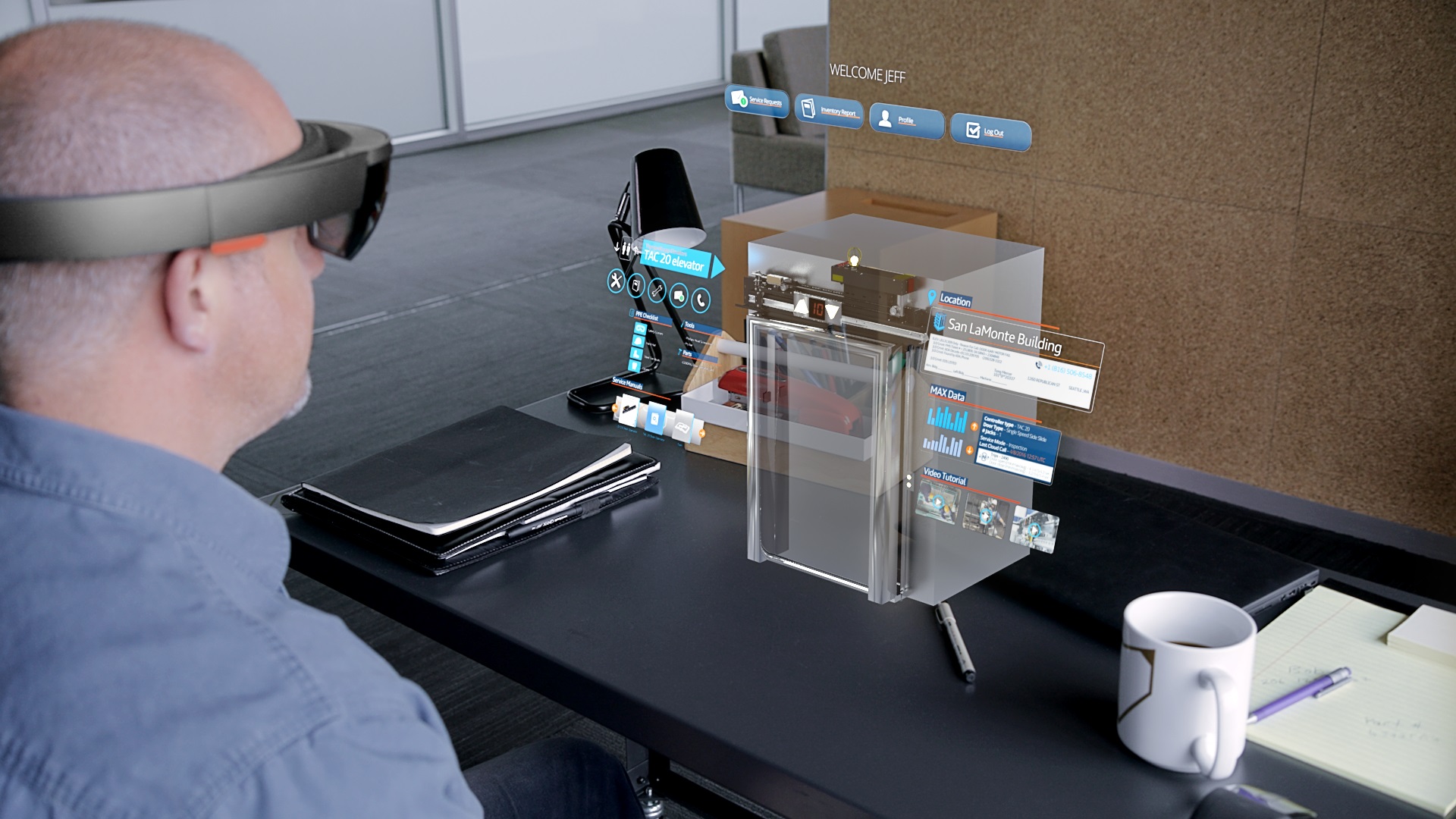

Using the predictive maintenance capabilities of the Azure IoT Suite, thyssenkrupp’s service technicians already identify problems with elevators, which allows them to make time-saving interventions and quicker fixes before it inconveniences their customers. Now, with the use of Microsoft HoloLens, they will be able to work hands-free while on the job and make remote calls to more experienced technicians who can walk them through solutions – and provide them with valuable on-site education.

Video produced and provided by thyssenkrupp.

“Predicting problems enables us to have fewer service interventions, and this equipment helps us do our job faster,” says Andreas Schierenbeck, CEO of thyssenkrupp Elevator. “Today our techs have a laptop or cellphone in one hand, or are checking information on laptops. While they’re doing that, they can’t work. But with HoloLens, they can speak with a control room, which guides them to replacing the right components. They can check their work and make sure they don’t have to come back for a second call. They can look at a 3D hologram of parts, explore the system and automatically order what they need. It’s an extremely helpful tool. This is important with an urban population that will grow by 3 billion over 3 years. In Manhattan, an elevator is built every day.”

One World Trade Center in New York City is one of many buildings where HoloLens will be used, as the site is already connected via the Microsoft Azure cloud with MAX, thyssenkrupp’s IoT-enabled predictive maintenance solution. The building has elevators that travel from the ground floor to the 102nd floor in just 60 seconds. When elevators decelerate, regenerative drives convert that energy into electricity, which significantly reduces the building’s carbon footprint.

“Utilizing an out-of-the-box Skype experience without any additional development required, thyssenkrupp’s 24,000 service engineers can now do their jobs safer, and more efficiently, by triaging a service call ahead of the visit,” writes Scott Erickson, general manager of Microsoft HoloLens, in a blog post coinciding with the announcement of this new technology. Initial field trials by thyssenkrupp Elevator have already shown that a service maintenance intervention can be done up to four times faster than before by using HoloLens.

For thyssenkrupp Elevator, HoloLens emerged after exploring the market for mixed reality devices.

“We tried many, but this is the technology we chose. It’s easier to apply and really easy to model,” Schierenbeck says. “You have a completely open image of the reality in front of you and all the data you want to access in your vision area.”

Erickson adds that using HoloLens is complimentary to MAX, which he describes as “thyssenkrupp’s game-changing service for elevators that leverages the predictive maintenance capabilities of Azure IoT.”

In the summer of 2014, thyssenkrupp began collaborating with Microsoft and global systems integrator CGI to develop a solution that securely connects thyssenkrupp’s thousands of sensors and systems in its elevators to the cloud. With the Microsoft Azure IoT Suite, thyssenkrupp captures elevator data – such as motor temperature, shaft alignment, cab speed and door functioning – and transmits it to a single dashboard. This provides real-time data visualization of immediate issues and information for future management.

“They’ve been with us from the beginning,” says Kevin Miller, a program manager who has worked extensively with thyssenkrupp Elevator as an Azure IoT engineer for Microsoft. “The company came in with an open mind and an aggressive focus on understanding business better and making it better, putting sensors on a subset of elevators near Microsoft. The telemetry we received from those systems was really step one of this process.”

The company’s portfolio includes passenger and freight elevators, escalators and moving walks, passenger boarding bridges, stair and platform lifts, as well as tailored service solutions for all products.

“There were some pretty profound realizations that thyssenkrupp came to during that process, which is a pattern we’ve started to see over and over as companies embrace IoT. They’ve discovered things about their business they’d never known before,” Miller adds. “They were maintaining more often than they needed to, when the data showed they could adjust maintenance windows, which meant sending in trucks less often. This saved 15 percent on maintenance, which was their biggest internal cost. They were very excited about this IoT thing after this.”

Powered by Microsoft Azure IoT, this predictive maintenance empowered thyssenkrupp to give 95 million hours of new availability per year of operation to elevator passengers all over the world.

Thanks to the work thyssenkrupp Elevator did with Microsoft, they were able to understand failures better, and what was likely to fail in the future, once they had integrated new data and analysis into ordering and scheduling systems.

“At that point, they’re very good at getting the right parts on the truck. They’re saving even more money, getting an increase in customer satisfaction and feeling transformative for the company,” Miller says. “Now they can be pro-active.”

With this latest step of the partnership between the two companies, thyssenkrupp Elevator can take its services to the next level, offering a product that always works because they’re able to predict failures and fix problems before costly stalls.

“When you want to deploy a project like this globally, you want a partner with a certain level of expertise and global reach,” Schierenbeck says. “Microsoft offers all that and was also keen on exploring business transformation. Our visions are perfectly aligned.”