Digital innovation on wheels: How Renault Sport Formula One Team races for success

With sleek cars reaching 220 miles per hour, Formula One racing is a pinnacle of aerodynamics and engineering finesse. In recent years, the global event has also become a sport of computing prowess, an essential shift to process the vast amounts of data generated in building, testing and racing high-speed machines.

Among this season’s 10 teams, Renault Sport Formula One Team stood out as a rising star with big goals. After supplying engines to other teams in recent years, the French automaker entered the race as a full constructor team in 2016, which means it’s responsible for building the entire car. It reorganized its two factories in England and France, invested in staff and resources, and laid out a multi-year plan for winning a championship.

The team has since ascended in rankings every year, rising from a dismal ninth place in 2016 to sixth place in 2017. It ranked fourth at the end of this year’s 21-race season, which wrapped Sunday at the Abu Dhabi Grand Prix in the United Arab Emirates.

“We are at the top of the midfield,” says Pierre d’Imbleval, Renault Sport Racing chief information officer. “What will change the game is how we embrace technology that makes us even more efficient. It’s about being smarter in the way we work.”

Because Formula One limits the number of physical test runs and wind tunnel hours teams can perform, Renault’s engineers rely heavily on computer simulation to gain a razor-thin edge. To adapt their cars for each race, they run thousands of digital scenarios with Azure Batch to fine-tune modifications, pit stop tactics, tire combinations and other strategies.

The cloud’s scalable compute power enables the team to cost-effectively run big loads of virtual machines in a matter of minutes – work that previously took hours on-premise. Speed is critical and the innovation cycle brutal; the team often designs, tests, manufactures and ships parts in a few days during the race season.

“There are so many factors that are constantly changing and can affect race strategy: track temperature, tire performance, what the other drivers are doing,” says Mark Everest, the team’s information systems development manager. “Simulation helps us quickly understand how to configure the car for a particular track.”

Renault Sport Formula One Team is also exploring Microsoft’s artificial intelligence tools to find insights from the 30 to 50 billion data points it generates every race weekend. Much of the data is normal feedback, but the amount of data makes it challenging to know what’s abnormal. Azure Machine Learning can parse the data for anomalies, so engineers spend less time manually checking data channels and more time on innovation. The technology can help the team as it accumulates more data every year.

“How do we use that extra data?” says Everest. “You can’t just get more people to look at the data. You have to find smarter ways of working with that data, and AI is going to be one of those ways.”

The team is also studying AI as a way to analyze tire behavior, a complex challenge involving thousands of factors from track conditions to the type of tire compound.

“Tires are much more complex than lumps of rubber, and understanding how they’re going to behave is a serious challenge,” says Everest. “So AI would be good at spotting patterns.”

Already, Renault Sport Formula One Team has accelerated its design and build process – a system involving 20,000 parts per car – with Microsoft Dynamics 365 and Power BI. It’s exploring edge computing for race-day analytics. And it is deploying Microsoft HoloLens to visualize simulations in 3D, which is leading to better understanding and collaboration.

The mixed reality project stemmed from an initiative encouraging IT employees to spend 10 percent of their time on innovation, an essential tactic for trying to overcome teams with larger budgets and staff.

“When you’re not as big as the other teams, it is a really exciting challenge to try and win championships,” says Everest. “Technology to me is the only way to do that. It is about innovating and working more efficiently and out-engineering the competitors.”

But innovation requires change, which d’Imbleval says can be difficult in the risk-averse culture of motor sports. He says the bi-weekly pressure to deliver top performance in high-profile Formula One races – watched 1.4 billion times on TV last year – can make people resistant to change. He views his role as CIO as strengthening Renault Sport Formula One Team with technology, while encouraging innovation and collaboration.

“That’s the challenge of leaders in this industry, to make people more confident to take risks,” d’Imbleval says. He then shares one of his favorite quotes on disruption: “Edison’s electric light did not come about from the continuous improvement of the candle.”

“That’s really true,” he says. “You need people to improve the candle, because that is what you have to achieve your business. But you also need people who think, ‘Let’s get rid of the candle and reinvent out of the box.’”

Learn more about Renault Sport Formula One Team at Microsoft In Culture.

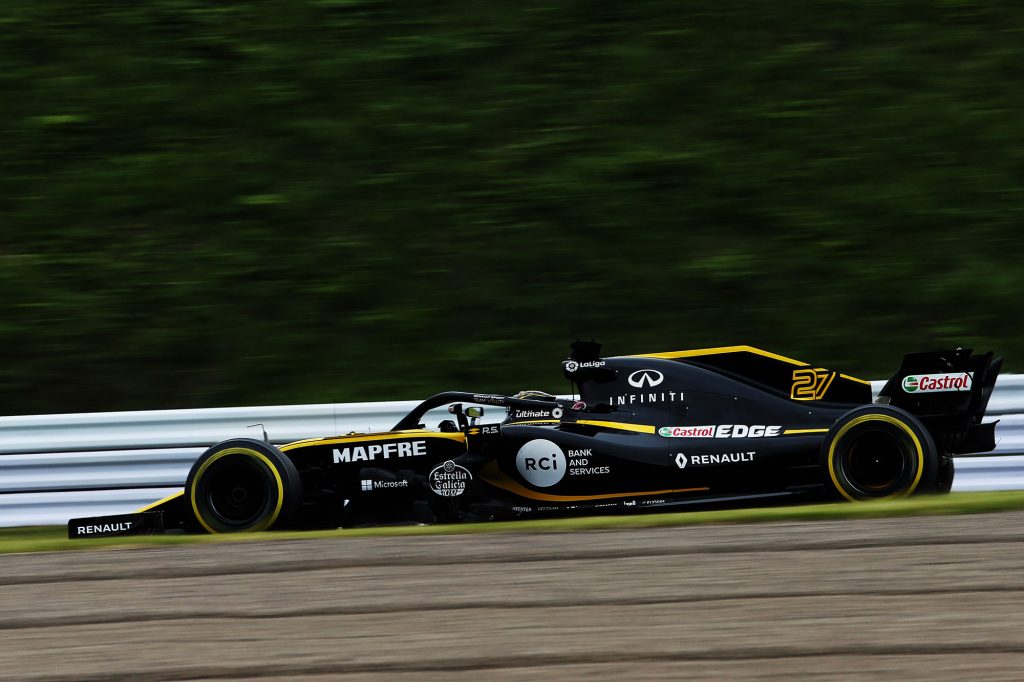

Top photo: Renault Sport Formula One Team car. (All photos courtesy of Renault Sport Formula One Team)